Coated abrasives

Coated abrasives by sia Abrasives are highly versatile, highly efficient and have a proven track record. With an annual output of 35 million square metres, we are one of the world's leading manufacturers of coated abrasives.

Manufacturing

Our coated abrasives are your key to a perfect surface. Like any top-quality product, the essence of a good abrasive is the right components and the perfect structure. Find out here how they are manufactured:

Abrasive structure

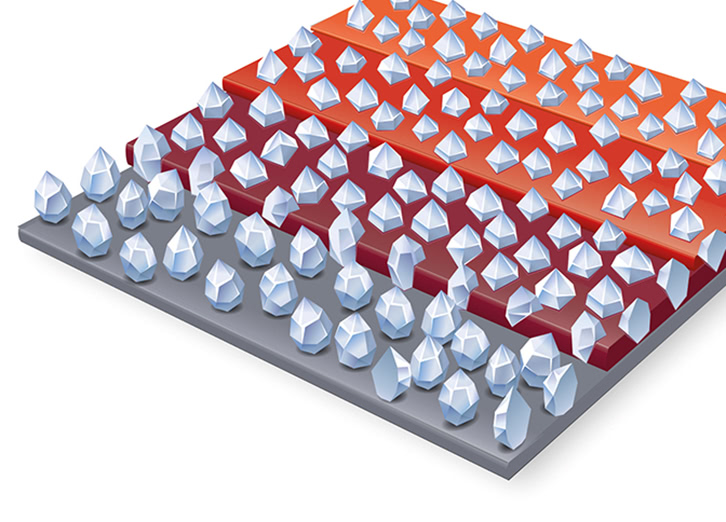

The five key components of a perfect surface finish are – backing, base coat, abrasive grit, size coat and additional coating.

Grit coating method

The right method ensures optimal application of the abrasive grit to the backing.

Production

Our premium products are made in a highly stable eight-step production process.

Standard items

Fabrication by stamping or lasering for a variety of abrasive formats.

Shaping by high-performance stamping

Our abrasives are shaped using cutting blades and a yoke-type punch. High-performance punching machines are used to make simpler formats. These machines use precision tools with carbide dies which allow multiple formats to be punched simultaneously during each stroke. This places high demands on the accuracy of the tool and the punching machine.

Shaping using laser technology

The application of laser technology during abrasives manufacturing makes it possible to manufacture abrasive discs with very small holes and a large number of holes per disc. Today, this technology is used especially in the manufacture of multi-hole abrasive discs. The hole pattern of the FiboTec discs provides improved dust extraction, significantly reduced clogging and longer service life for the abrasive materials.