Bonded abrasives

Bonded abrasives by sia Abrasives are premium products of the highest quality standard. All products are continuously tested in our research and development at sia Abrasives. This enables us to guarantee highest levels of safety in demanding applications.

Products

We can offer you the right solution for a wide range of materials. Depending on application, a straight or depressed centre disc of matching thickness is recommended for each material.

Cutting discs

Our siacut abrasive cutting discs are noted for their long lifetime and precise cutting properties.

Grinding discs

Our siagrind grinding discs stand out due to their very high cutting power, long service life and comfortable handling.

Test centre

We make a distinction between safety and performance tests. We carry out this procedure at the sia Abrasives test centre in Frauenfeld, in northern Switzerland, to guarantee your safety. Tests to ensure consistent production batches and comparison tests to assess competitors are also part of the process.

Manufacturing

Our resin-bonded abrasive cutting and grinding discs are produced in special machines by mixing a blend of abrasive minerals, fillers, powder resin and liquid resin and pressing this into cutting discs of different thickness and diameter. In order to withstand the enormous centrifugal forces to which the discs are subjected, glass fibre fabric is embedded into the actual abrasive.

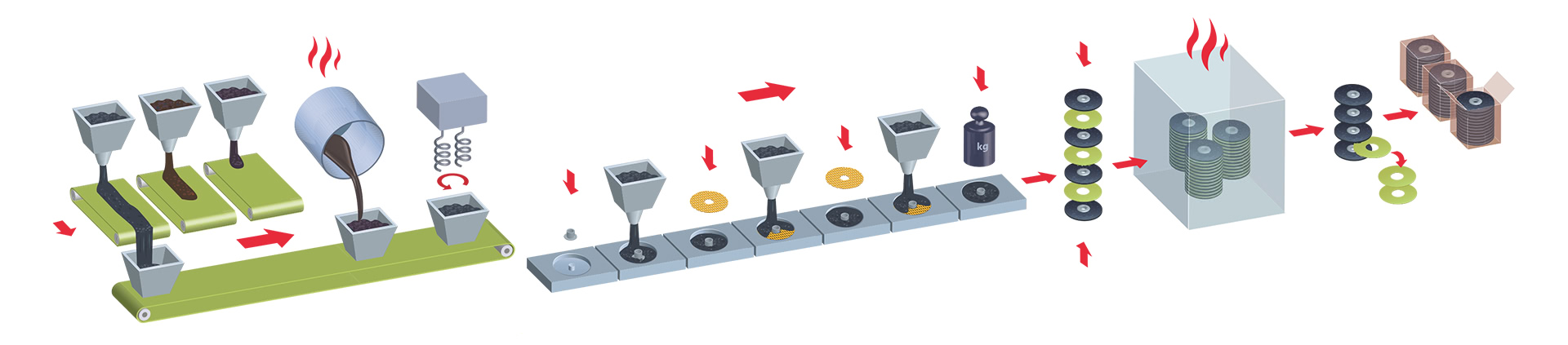

The process of manufacturing a bonded abrasive disc involves three steps:

1. Treatment of the abrasive disc mixture

The abrasive grits soaked with phenolic liquid resin are mixed with a powder resin, filler and auxiliary materials to produce a pourable mix.

2. Shaping of the mixture to produce blanks

The mould is now filled alternately with screened mixture and fibre mesh. Both components are compacted together by a hydraulic press.

3. Baking/curing in the curing oven

Finally, the finished "green compacts" from step 2 are clamped between steel plates and cured in a chamber oven at 200 °C.